Lithium-ion batteries have revolutionized the modern world, powering a wide range of devices from smartphones to electric vehicles. Understanding how these batteries work, their production process, and the sourcing of lithium is crucial for comprehending their impact on our lives. Moreover, it is essential to explore the future of lithium-ion batteries and alternative technologies in case the availability of lithium becomes limited. This article delves into the fascinating world of lithium-ion batteries, providing insights into their functioning, production, sourcing, and the prospects for future energy storage solutions.

Table of Contents

How Lithium-Ion Batteries Work

Lithium-ion batteries operate on the principle of electrochemical reactions. The battery consists of three main components: a cathode (positive electrode), an anode (negative electrode), and an electrolyte. During charging, lithium ions flow from the cathode to the anode through the electrolyte, where they are stored in the anode’s porous structure. During discharge, the ions reverse their flow, generating electrical energy.

Production of Lithium-Ion Batteries

The production process of lithium-ion batteries involves several stages:

a. Electrode Manufacturing: The cathode and anode materials, typically composed of lithium compounds, are coated onto metal foils. The cathode commonly utilizes lithium cobalt oxide (LiCoO2), while the anode incorporates graphite or other carbon-based materials.

b. Cell Assembly: The prepared electrodes, along with a separator, are assembled into a cell. The separator ensures the separation of the cathode and anode while allowing the flow of lithium ions.

c. Electrolyte Filling: The cell is filled with a liquid or gel electrolyte, often containing lithium salts dissolved in organic solvents. The electrolyte facilitates ion movement between the electrodes.

d. Sealing: The cell is sealed to prevent leakage and maintain a controlled internal environment.

Lithium Sourcing

The majority of lithium used in lithium-ion batteries is sourced from several countries:

a. Australia: Australia has significant lithium reserves and is one of the world’s largest producers. The Greenbushes lithium mine in Western Australia is a prominent source.

b. Chile: Chile possesses vast lithium reserves in its salt flats, particularly the Salar de Atacama. The region is known for its lithium extraction through evaporation ponds.

c. Argentina: Argentina also holds significant lithium resources, primarily in the Salar del Hombre Muerto region.

The Future of Lithium-Ion Batteries

Lithium-ion batteries are expected to play a vital role in the future of energy storage due to their high energy density and efficiency. However, considering the limited availability of lithium, alternative technologies are being explored:

a. Solid-State Batteries: Solid-state batteries, which use solid electrolytes instead of liquid or gel-based electrolytes, show promise for higher energy density, enhanced safety, and potentially longer lifespans.

b. Lithium-Sulfur Batteries: Lithium-sulfur batteries have the potential to surpass the energy density of lithium-ion batteries. Ongoing research aims to address the challenges of sulfur electrode degradation and the formation of unwanted byproducts.

c. Beyond Lithium: Scientists are exploring other elements such as sodium, magnesium, and zinc as potential alternatives to lithium for future battery technologies. These elements offer abundant resources and could help mitigate concerns about lithium scarcity.

Summary

In conclusion, lithium-ion batteries have truly transformed the way we power our devices, fueling our modern world with portable energy. From smartphones to electric vehicles, these batteries have become indispensable. By delving into their inner workings, production methods, and the sources of lithium, we gain a deeper understanding of their impact on our lives.

While lithium-ion batteries continue to hold great promise for the future of energy storage due to their impressive energy density and efficiency, it is important to consider the potential challenges posed by the availability of lithium. As we strive for sustainable and long-lasting solutions, researchers are exploring alternative technologies that could shape the landscape of energy storage.

Exciting advancements are being made in the realm of solid-state batteries, which offer enhanced safety and higher energy density through the use of solid electrolytes. Lithium-sulfur batteries also show tremendous potential, with their ability to surpass the energy density of traditional lithium-ion batteries. Overcoming certain obstacles, such as sulfur electrode degradation, will be crucial for their widespread implementation.

Moreover, scientists are looking beyond lithium and investigating elements like sodium, magnesium, and zinc as potential alternatives. These abundant resources offer a promising avenue for future battery technologies, alleviating concerns about lithium scarcity and ensuring sustainable energy storage solutions for years to come.

As we navigate towards a greener and more efficient future, the development of advanced energy storage systems remains a key focus. By continuing to push the boundaries of innovation and exploring alternative technologies, we can shape a world where reliable and sustainable power is readily available to meet the evolving needs of our society.

How Emerging Technology Trends Are Reshaping Our World in 2025

In an era where technological innovation evolves at lightning speed, staying ahead of the curve can …

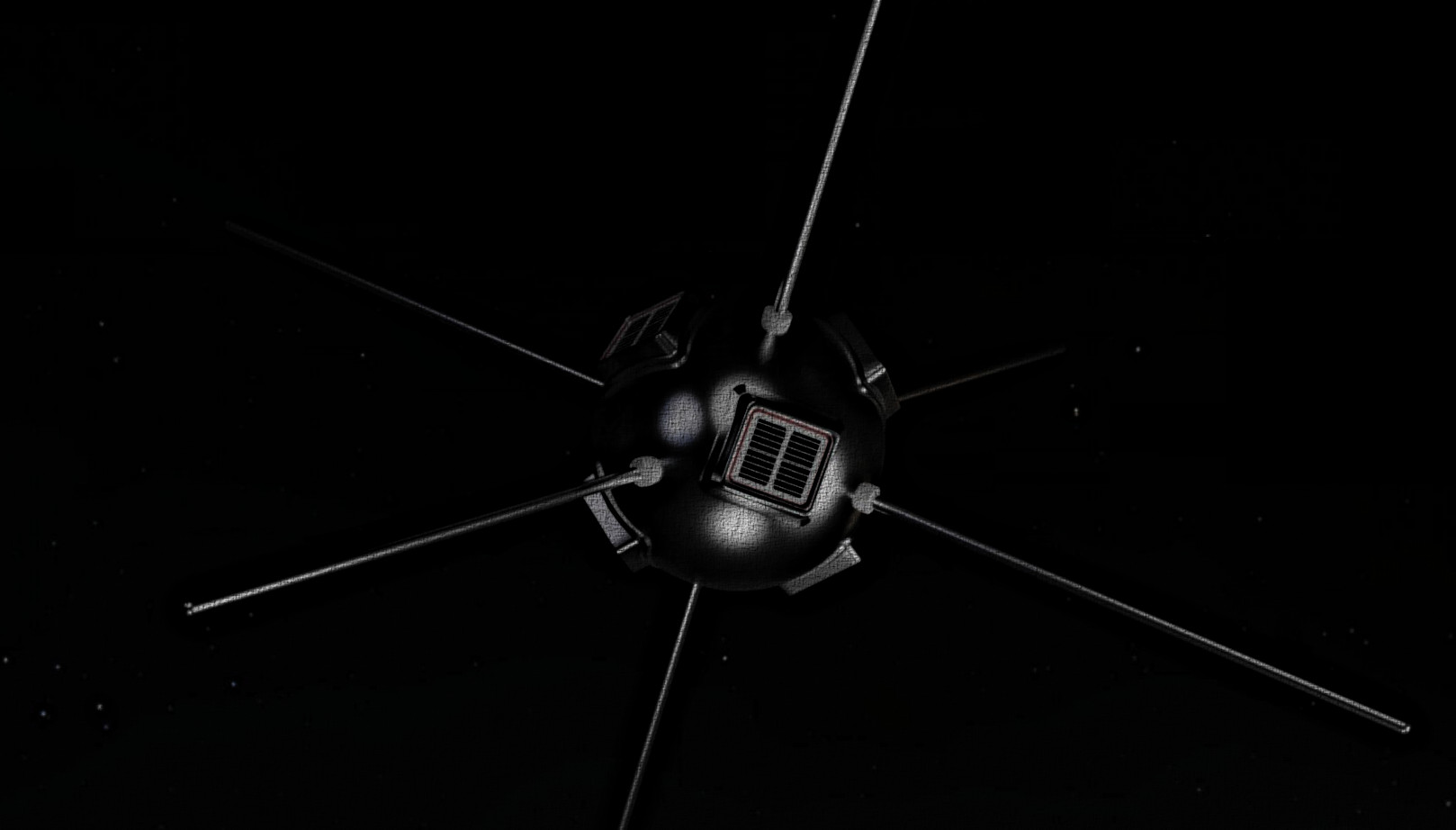

Vanguard 1: Earth’s Oldest Artificial Satellite May Soon Return to Earth

In an exciting move that could reshape the history of space exploration, the United States is consid…

Technology Terms Explained

The technology world is full of acronyms and specialized terms, including essential Technology Terms…